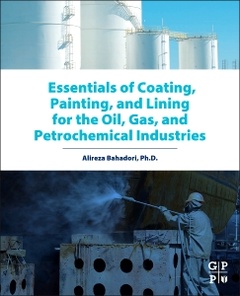

Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical Industries

Auteur : Bahadori Alireza

With the oil and gas industry facing new challenges?deeper offshore installations, more unconventional oil and gas transporting through pipelines, and refinery equipment processing these opportunity feedstocks--new corrosion challenges are appearing, and the oil and gas industry?s infrastructure is only as good as the quality of protection provided and maintained. Essentials of Coating, Painting, and Linings for the Oil, Gas, and Petrochemical Industries is the first guide of its kind to directly deliver the necessary information to prevent and control corrosion for the components on the offshore rig, pipelines underground and petrochemical equipment. Written as a companion to Cathodic Corrosion Protection Systems, this must-have training tool supplies the oil and gas engineer, inspector and manager with the full picture of corrosion prevention methods specifically catered for oil and gas services. Packed with real world case studies, critical qualifications, inspection criteria, suggested procedure tests, and application methods, Essentials of Coating, Painting, and Linings for the Oil, Gas and Petrochemical Industries is a required straightforward reference for any oil and gas engineer and manager.

- Understand how to select, prime and apply the right coating system for various oil and gas equipment and pipelines – both upstream and downstream

- Train personnel with listed requirements, evaluation material and preparation guides, including important environmental compliance considerations

- Improve the quality of your equipment, refinery and pipeline with information on repair and rejection principles

Date de parution : 01-2015

Ouvrage de 830 p.

19x23.3 cm

Thème d’Essentials of Coating, Painting, and Lining for the Oil... :

Mots-clés :

abrasive blasting; acid-pickling; Adhesion of lining; adhesive material; aliphatic polyurethane paint; alkaline pickling; alkyd intermediate paint; alkyd primers; red lead; anodic etching; bituminous coating; bituminous coatings; bituminous paint; Blast; Bolting; cage type reinforcement; Cementation; ceramic; chemical inhibition; chemical-resistant paints; coal tar enamels; coal-tar enamel; Coating Materials; coating of subsea pipelines; Coating procedure; Coating schedule; cold-applied bituminous coating; concrete coating; Continuity of lining; cured coating; Curing; Defect Rate; degreasing; drying oil-type paints; enamel; Epoxy lining; epoxy polyamide intermediate paint; epoxy polyamide paint; epoxy polyamide primer; epoxy powder; extruded polyethylene coating; flame-cleaning; galvanizing; glass-lined; grease paints; heat-shrinkable tape; immersion process; inner and outer wrap; inorganic-lined; iron oxide; latex paint; Lining; Lining Installation; longitudinal reinforcement; Material selection; multicomponent liquid coating; nickel strike; packaging; packaging; asphalt mastic; mix vinyl paint; raw linseed oil; paint coatings; paint color coding; Paint materials; Paint schedule; pickled surface; plaster; plastic tape; polyethylene; Polyethylene coating; polymeric materials; Porosity; priming and painting; Protective Coatings; Repair of lining; rubber; rubber; chlorinated rubber; alkyd paint leafing; rust removal; spray; steam cleaning; Storage; tape-wrapped zone; thermoplastic resin; thermoplastics; thermosetting resins; troweled mortar lining; vinyls and chlorinated rubber paints; Vulcanizing; wash primer; welding; white alkyd paint; zinc coatings plus paint; zinc silicate paint; zinc-rich; zinc-rich epoxy paint; zinc-rich paints